from drone food delivery to the Huffman junction

Last week Uber Eats presented their new delivery drone and the “tech” press was there to inhale deeply.

One article indicated the drone will carry dinner for two and have a one way range of 8 minutes. It will fly from the restaurant to a central facility where the food is turned over to a driver to make the final delivery. This all seems complicated. The restaurant would be responsible for loading the drone and one can only hope there is little to no wait for a driver at the central facility. One might guess that it is actually slower and logistically more intensive than handing the meal off to a driver, that would go in the restaurant to pick up the food. It makes you wonder how food delivery became the pinnacle of tech. So much for making a sandwich.

drones to semiconductors

Contemplating drone food delivery made me think of a talk I gave at the University of Ottawa last month. I discussed advances in materials science and engineering that brought about a 3 order of magnitude decrease in device size in integrated circuits. That is real engineering and real innovation. With the industry quickly running out of nm left to shrink I also thought about problems or areas of development to which the accumulated knowledge might be applied. Energy harvesting struck me as ripe to benefit.

to thermoelectrics

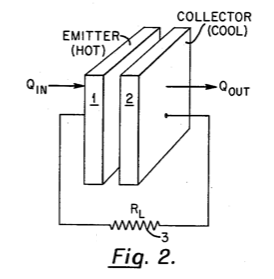

Thermoelectric materials are really nifty. They can generate electricity from low-grade waste heat or they can create a temperature difference when electricity is applied. Basically, one needs to maintain a temperature difference across two surfaces while having current flow therebetween. This is schematically illustrated below. The material system from which a thermoelectric structure is created must be a good electrical conductor and a poor thermal conductor. This is not a natural combination of properties, implying the material or system must be engineered.

to a 4 nm gap

In the talk I considered a Huffman Junction as detailed in US3,169,200. One of the disclosed structures is depicted in Fig. 2, reproduced below. Here, two plates are separated by an air gap. The gap is large enough to maintain a temperature difference, but small enough to allow tunnelling of electrons from the hot to the cold plate. An air gap of 4 nm is disclosed in the patent.

A structure of this dimension would not have been possible in 1965, when the patent issued. It probably was not feasible 15 years ago. But, today the semiconductor industry is fabricating structures on this scale.

I have not researched the technology to know if it would work. In fact, one could imagine radiative heat transfer between the surfaces. We also do not know how efficient it might be. It does though provide a nice example of an idea that may be brought to life with fabrication technology from another industry.

It also provides a poignant example of where money should be directed. Society can decide if it is more important to have our take-out food delivered to us by drone or tackle issues of energy use and efficiency. Which is more pressing?